Our disc packs are produced applying high grade stainless steel

(AISI-301), making sure large power, higher endurance to fatigue, and resistance to most environmental disorders.

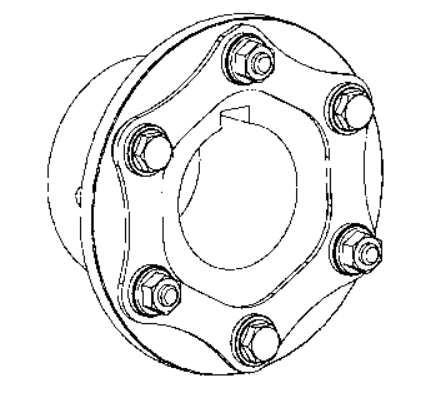

Disc couplings use unitized disc packs with the two six or 8 bolt models. The 8 bolt style and design can transmit higher torque than the 6 bolt style and design, nevertheless, it is not ready to accommodate as a lot angular misalignment.

Couplings could be fitted with overload bushings to protect the disc pack during momentary torsional overloads.

Couplings are presented within a variety of configurations to fit most applications. Also, ?¡¥s engineering department can customize a coupling to meet a lot of distinctive necessities this kind of as close coupled, drop-out centers, electrically insulated, vertical mounting, and safety couplings. A notable design made available by will be the reduced second (DI Type) coupling that meets the anti-flail gadget demands mandated in API-610 even though giving a very low weight and brief center of gravity to bearing distance.

The design and style and manufacture of disc couplings is integrated right into a licensed High-quality Program in accordance to ISO-9001 to fulfill the high top quality necessities of shoppers.

Rewards of the Disc Coupling

Eliminates the require for lubrication and coupling maintenance

Coupling may be inspected without having disassembly

Condition of disc packs can be inspected which has a strobe light while the machine is working

Note: It is actually not proposed that couplings be operated with out coupling guards.

Easy to assess gear misalignment

Torsionally rigid without having any backlash

No wearing components

\Resistance to harsh environments

Long daily life when adequately sized and aligned

High energy density (higher torque for a offered outside diameter)

Supports the API-610 Regular up  to three,800 RPM

to three,800 RPM

Unitized disc packs ensure repeatability required for meeting the balance and piloting prerequisites as mandated by API-610

Obtainable with Overload Bushings to safeguard the coupling from momentary torque overloads

Prevents the disc pack from staying plastically deformed

Allows for shorter BSE (shaft separation) simply because bolts is usually turned to face inward

Special orientation of bolts allows the bolts to be tightened utilizing a torque wrench instead of nuts (Regular would be to tighten nuts with torque wrench)

Disc coupling

Tags: